Sustainability report

PKF/POST believes in corporate social responsibility. Our approach is recorded in our CSR report for 2021: Sustainable DNA. In this report, we pay attention to the environment and to our social involvement, for example.

CO2 reduction

We are an active promoter of natural packaging materials. Wood is the main raw material for the pallets produced by PKF/POST. We see the use of natural raw materials as our obligation to sustainably safeguard our world. All our pallets are produced entirely from wood sourced from European production forests.

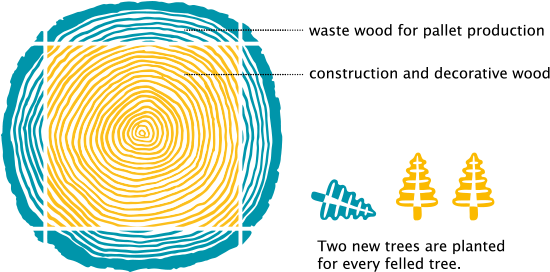

In these forests, two new trees are planted for each tree felled. Consequently, the area of production forests is growing strongly. Thanks to the young trees, more CO2 is absorbed from the air than is released during the production of pallets. The forests are managed according to the rules of the PEFC (Programme for Endorsement of Forest Certification). This is a global non-profit organisation that promotes sustainable forestry independent of any government.

Contrary to popular belief, the pallet industry actually only processes leftover wood. It is a by-product of wood sawmills. The heart of a log is the best quality wood, mainly used in the construction industry and furniture manufacturing. Sawmills regard the outer edges of a log to be a by-product, and it is this wood that is used to produce wooden pallets.

Dry wood

PKF/POST processes mainly dried wood. This is a much more sustainable process than the use of freshly sawn wood, that would be dried after the production of the pallets. The environmental advantage lies mainly in the transport factor. Due to the wood no longer containing thousands of litres of moisture, dry wood weighs much less than freshly sawn wood. A truck can therefore transport 30% more dry wood, leading to lower fuel costs for suppliers, and lower CO2 emissions.

The use of dry wood also benefits the accurate dimensioning of pallets. Furthermore, our planing-cutting mill ensures that all the wood to be processed is calibrated according to the agreed dimensions. This also positively benefits the automatic processing at our plant and for our customers. It results in less waste and less downtime of production processes, and is therefore better for the environment.

Stichting Markering Houten Verpakkingen (SMHV, Foundation implementing the Dutch Wood Marking Program) is the organisation responsible for monitoring and controlling the sterilisation of wooden packaging materials in the Netherlands. PKF/POST is registered with this foundation and therefore permitted to apply heat treatment.

PKF/POST is PEFC registered, for Finsterwolde registration number PEFC/30-31-379 and for Venlo registration number PEFC/30-31-389.

No waste

When sawing wood for our pallets, we work as efficiently as possible, thus reducing the volume of waste material to virtually zero. The resultant shaving curls and sawdust are mainly used as bedding in stables. Leftover wood is machined into production material for chipboard and pallet blocks.

Trucks and machines

Thanks to the commissioning of so-called LHVs (longer heavier vehicles), PKF/POST now transports 50% more pallets per trip. This translates into a fuel saving of 30%. Our modern trucks are all fitted with Euro-6 engines, which is the latest emission norm for combustion engines in Europe.

We are constantly working at reducing energy consumption in all our production processes. When replacing and extending our range of machines, the energy consumption of new machines is a very important selection criteria. Following recent modifications to our working sites, all exterior lighting has been replaced by LED fittings. The same applies to the lighting in our production halls.